The foam-bonding blog

In the last few years, foam bonding has become an increasingly demanding business. Many key application fields of foam – foam converting and upholstery, mattress manufacturing and automotive – face multiple challenges, such as cost pressure, workspace contamination and rising consumer demands. In this article, we present solutions that work for any of these industries.

To start off, we have prepared a few articles of general interest on topics such as the benefits of PU foam or the different adhesive types available. Later, we dive into the three industries: mattress manufacturing, upholstery and automotive, and talk about individual topics, challenges, and solutions.

Our latest articles from the foam universe

Making a valuable contribution to the environment through mattress recycling

In the past, supply shortages have increased due to the limited availability of CR. The SIMALFA®-team has therefore expanded its adhesive portfolio with CR-free adhesives that meet current and emerging regulations.

CR-free adhesives

In the past, supply shortages have increased due to the limited availability of CR. The SIMALFA®-team has therefore expanded its adhesive portfolio with CR-free adhesives that meet current and emerging regulations.

All foam-bonding blog posts

The trustworthy ally in the automotive industry

The SIMALFA® adhesives have been specifically developed and optimized to meet the high requirements of today's production of automobiles. With SIMALFA® you achieve an immediate, high-quality bonding of your work piece.

CR-free adhesives

In the past, supply shortages have increased due to the limited availability of CR. The SIMALFA®-team has therefore expanded its adhesive portfolio with CR-free adhesives that meet current and emerging regulations.

Improved efficiency with fast drying adhesives

In the production of mattresses, short waiting times and instant packaging can significantly improve efficiency. For the ultimate speed of the inline production and the best quality of the mattress, we designed SIMALFA® 360.

The importance of mattress recycling

The SIMALFA® adhesives have been thoroughly tested for contaminants and do not pollute the environment during mechanical or chemical recycling. Due to their water base, they are inherently sustainable.

SIMALFA®: Solutions for mattress manufacturing

Pack mattresses immediately after production. Maximize efficiency, reduce storage space requirements and increase process reliability at the same time.

SIMALFA® 825 – the best adhesive for upholstery

We put our expert for upholstery adhesives, Mariusz Stróżak, on the new SIMALFA® 825. Mariusz’s conclusion: „The best adhesive for foam bonding in the upholstery industry I have ever worked with.“

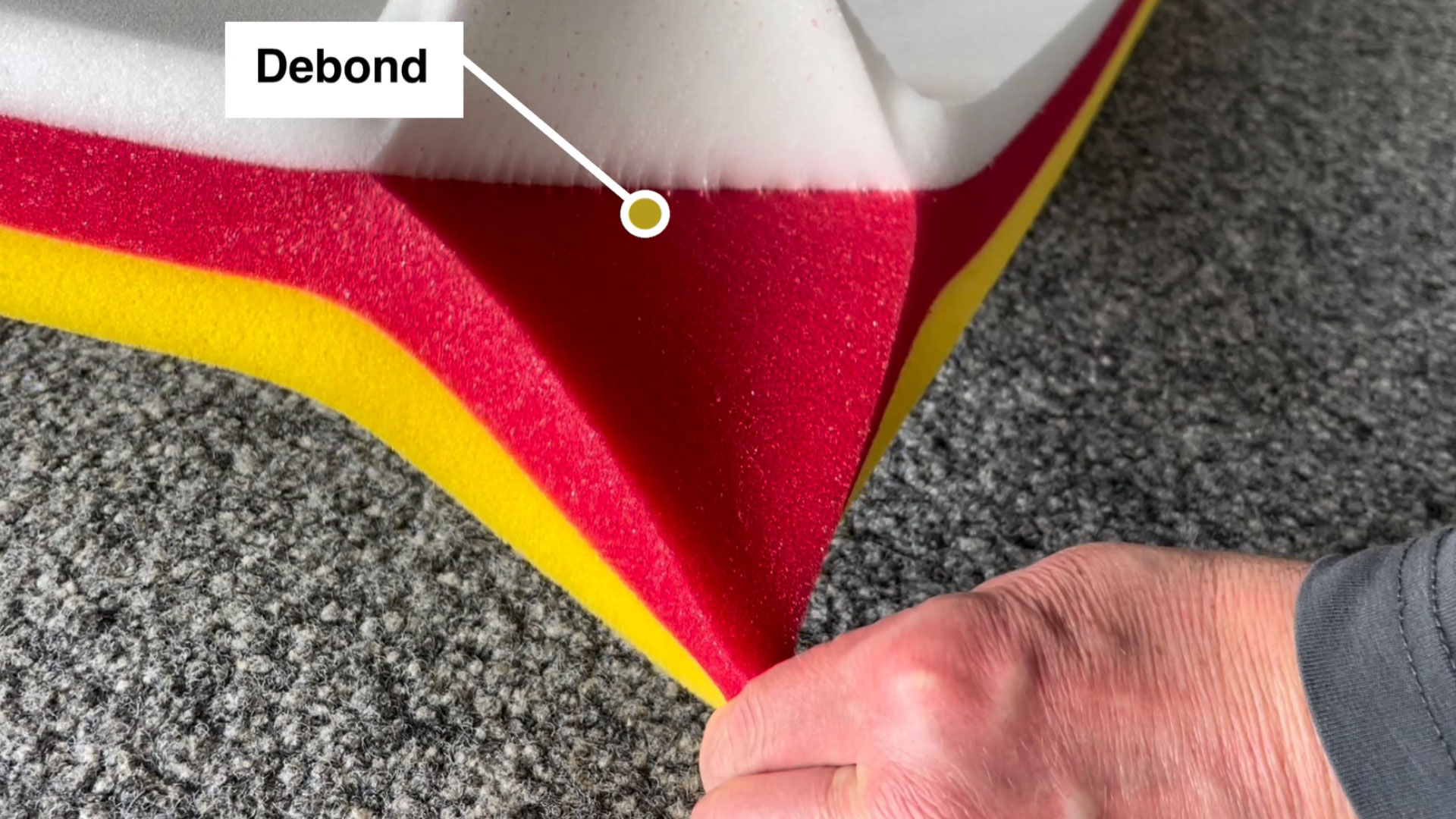

Tackling overspray, production delays and cost pressure in upholstery

Strong and long-lasting hold as well as safe application should be given. The SIMALFA® adhesives have been specifically designed to meet these high requirements.

How rolled mattresses optimize your production

Long drying times, high space requirements and the so-called "memory effect" are a thing of a past. SIMALFA® 360 is the first choice for an efficient mattress production.

Making a valuable contribution to the environment through mattress recycling

In the past, supply shortages have increased due to the limited availability of CR. The SIMALFA®-team has therefore expanded its adhesive portfolio with CR-free adhesives that meet current and emerging regulations.

Adhesive types

The proper type of adhesive needs to be chosen based on the requirements of the production process. We will show you how you can find the perfect adhesive for your individual needs.

Roller coating in mattress manufacturing

The usage of rolling equipment maximizes your output while the application quantity of the adhesive can be reduced to a minimum and the whole process is extremely economical.

Adhesive applications for foam glue

SIMALFA® adhesives can be applied manually or automatically - both with spray guns or roller coaters. Find the right application method for your production.

Wet contact adhesives for gluing foam

Foam adhesives are often exposed to high tensile forces while the adhesive is still in its drying process. SIMALFA® wet contact adhesives are known for their strong instant tack and therefore optimal for bonding under tension.

THE NEXT LEVEL for mattress manufacturing

SIMALFA® adhesives can be applied manually or automatically - both with spray guns or roller coaters. Find the right application method for your production.

The benefits of PU foam

With SIMALFA®, PU foam can be bonded with almost every other material. But how can the glue be applied most efficiently and economically?

SIMALFA® Competence Center

SIMALFA® adhesives can be applied manually or automatically - both with spray guns or roller coaters. Find the right application method for your production.