Adhesive types

The right choices for foam-bonding glue in mattress and furniture production as well as transportation.

Adhesives play a crucial role in manufacturing industries such as mattress manufacturing, foam converting, upholstered furniture, or automotive. Facing a broad variety of requirements, the proper type of adhesive needs to be chosen based on the requirements of the production process, the materials to be bonded and the application method. Here is a brief overview of solvent-free solutions.

In general, one can differentiate solvent-based and solvent-free adhesives. Whereas solvent-based glue was highly relevant for adhesive applications in the past, today, solvent-free adhesives are the industry-standard for any high-quality production. Solvent-free solutions provide healthier environments for users, a high performance concerning instant tack and require less application of glue (thus enabling savings). Therefore, all SIMALFA® adhesives are water-based and 100% solventfree. Another differentiating factor is whether the adhesives are formulated as one or two components. Both product groups have their advantages, as will be explained below.

Mattress production: roller applications

For mattress manufacturing, roller application is the most efficient way to set up a highly automated high-quality production line. The adhesive is evenly applied to the foam layers with a double roller. This method is very efficient because no adhesive is wasted due to overspray and the application quantity required is extremely small.

If the production line with the roller coater can be adjusted precisely, the adhesive coat will dry very fast. In the inline production of mattresses, roller coating is used as a standard, often in combination with force dried adhesives. After application, such adhesives must be dried in an infrared drying tunnel or a circulating air oven before placing the next foam layer on top. As the glue is already dry at this point, the production can continue immediately and at the end of the process, the mattress can be packaged instantly after gluing the last pieces together.

Whether using spray-guns or a roller application, one component adhesives are the way to go for bonding different layers of foam. SIMALFA® 3031 is one of our one component foam-specialist adhesives with a wide range of use cases. It is suitable for all industries and bonds any kind of upholstery material. This wet-contact adhesive only requires a small application quantity to stick instantly and strongly. Because of the low quantity and its special formula, the drying time of SIMALFA® 3031 is extremely short. Additionally, the adhesive distinguishes itself by its outstanding flexibility and heat resistance.

In its original form, SIMALFA® 3031 is applied as one component, but to boost the instant tack, an accelerator can be added. To achieve the best mixing proportion of the two components and to enable a flexible adding of the accelerator, we developed our patented on-demand application system. By pressing a button on the spray gun, the accelerator boosts the instant tack.

Furniture production: spray applications

In the world of furniture production, adhesives need to be capable of bonding with a wide variety of materials including wood and plastics. For such applications, such as the bent edges of furniture, two-component adhesives are beneficial: Their instant tack is even stronger, which ensures the foam stays securely in place.

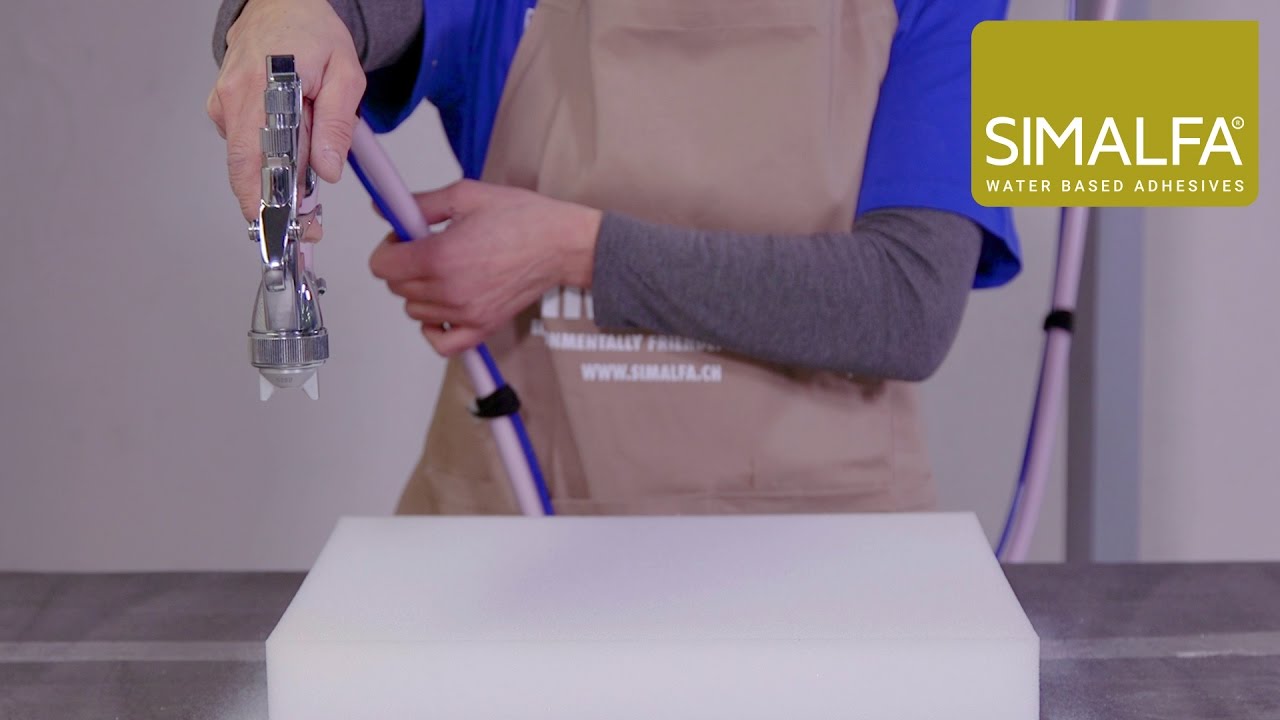

A manual spray gun is a frequently and successfully used application method in the upholstery, automotive and foam converting industry. A precise application is enabled through the adjustable airflow and width of the spray pattern. To transfer the adhesive from the container to the gun, we offer different systems: The simplest solution is our own invented Free Flowing System, which works with gravity alone just by placing the container above the workspace. If the adhesive has to be stored on the same horizontal height as the workspace, our Easy-2-Pump System is a helpful choice for two-component adhesives. The following tutorial video will give you an insight about spray application:

Sticking to their job – overspray-free adhesives

One concern with spray application systems is so called overspray. By spraying the adhesive over the edges of the foam, the workspace can get soiled, which can lead to stains on the products.

Additionally, more adhesive is released into the air, which can negatively impact working conditions. To solve this problem, we searched for a way to prevent overspray and found it in a net like-spray pattern.

Our SIMALFA® 315 OF (overspray-free) is a fast-setting adhesive that is excellent for mattress manufacturing and foam converting. In addition to its overspray-free technology, this adhesive is also the world’s first frost-resistant, dispersion-based wet contact adhesive for foam bonding.

It is applied as one component and the glue lines stay soft after drying out. It can bond a wide range of materials and can be applied manually or automatically. In the first few moments after applying, the bonded pieces can be repositioned, which is beneficial for mattress manufacturing.

The Easy-2-Pump System includes pumps guiding the adhesive from their storage container to the workspaces. It is simple to supply several workspaces with one Easy-2-Pump System. The adhesive can be sprayed manually using a spray gun. Thanks to the pumps, the adhesive can be used further away from the container and at a different or the same horizontal height.

Alternatively, the Free Flowing System simply utilizes gravity to transfer the glue from the container to the spray gun. Without any additional pressure – just a container above the workspace and a hose routed downwards – the Free Flowing System is the easiest way to apply the glue to your PU foam. Learn more about PU foam in the upholstering industry. Our local team will be thrilled to assist you with the installation of your equipment.

Although all our adhesive types are naturally sustainable because of their water base, we are continuously working on new, even more eco-friendly products. In 2018, we were able to launch our first chlorine and halogen-free formulated adhesives. One of them is SIMALFA® 374, which is perfectly suitable for upholstered furniture. Due to its two-component system, it has an excellent green strength for all kinds of foams and other upholstery materials such as wood.

Furniture experts and milestones for sustainability

SIMALFA® 825 is a two-component wet-contact adhesive with very high flexibility. It has been specifically developed for the upholstery industry and is used for bonding foams such as latex, polyether and PU foam as well as PE, PP, wood, upholstery materials, cardboard and felt. It is therefore an excellent option in the production of furniture because a single adhesive can be used for all the different types of material.

We asked our expert for upholstery adhesives, Mariusz Stróżak, to put the new SIMALFA® 825 through its paces. Mariusz has worked in the upholstery industry for more than 20 years and has tested countless brands of adhesives from different manufacturers. His conclusion: “The best adhesive for bonding foam in the upholstery industry that I have ever worked with.”

Read the full interview with Mariusz Stróżak here.

Transport industry: meeting regulations as well as the highest production standards

In the transportation industry, certifications to meet the increasing number of regulations are becoming more and more important, as are additional criteria such as heat resistance.

A significant technical challenge is the bonding of foamy materials with non-porous ones. SIMALFA® 3217 is suitable for usage in the foam converting and automotive industry for bonding foams such as polyether, latex, PU and PE foam. These materials are used in the automotive industry because for seat repairs, foam bonding is essential too. Additionally, SIMALFA® 3217 is distinguished by its high heat resistance, which is another crucial requirement in the automotive industry.

For public transport vehicles or the interior of airplanes, non-flammability is a crucial factor – and the speciality of our flame-retardant SIMALFA® 308 FR. It can be applied with spray guns and because the glue lines stay very soft after drying out, the quality of the produced parts stays excellent.

Still haven’t found what you’re looking for?

The adhesives presented above are of course only part of our full range of options. We offer several other adhesives with specific characteristics – all of them designed to meet the challenges of our different clients and their applications.

Especially for the bonding of plastic, we developed SIMALFA® 825, which is distinguished by an excellent tack to plastic surfaces.

Secure your personal appointment

Do you need support or advice? We love to share our know-how. Schedule your appointment now!

Read more articles

CR-free adhesives

In the past, supply shortages have increased due to the limited availability of CR. The SIMALFA®-team has therefore expanded its adhesive portfolio with CR-free adhesives that meet current and emerging regulations.

Wet contact adhesives for gluing foam

Foam adhesives are often exposed to high tensile forces while the adhesive is still in its drying process. SIMALFA® wet contact adhesives are known for their strong instant tack and therefore optimal for bonding under tension.

Tackling overspray, production delays and cost pressure in upholstery

Strong and long-lasting hold as well as safe application should be given. The SIMALFA® adhesives have been specifically designed to meet these high requirements.