Improved efficiency with fast drying adhesives

In the manufacturing of mattresses, efficiency of production is key for a profitable business considering that the drying process after gluing can be a significant time factor. It has now been nearly 20 years since the first roller coater for the application of SIMALFA® water-based adhesives was invented. Always having been on the front lines of research and development of high-quality adhesives, we are proud to offer a wide spectrum of products designed to optimize manufacturing processes worldwide. Our SIMALFA® glue dries instantly, so the mattress can be packaged immediately after gluing without risk of mould or bad odours.

Does your production process include roll packaging, perhaps to simplify shipping? No worries, the instant tack of our adhesives is strong enough to keep every layer in place, seconds after gluing.

The evolution of mattress manufacturing

We developed SIMALFA® more than 30 years ago following the ambition to create a foam adhesive that was safe for producers and more sustainable for the environment than solvent-based adhesives, but of even higher quality. Today we are proud to have achieved that goal, to lead the global market and to support our clients in adapting to new challenges. The world never stands still, and consumer needs are constantly changing.

In this digital age, online shopping has become one of the most popular ways consumers purchase mattresses and strong competition is putting pressure on prices and profit margins. To withstand these challenges, efficient production processes and the proper raw materials are essential. In the production of mattresses, short waiting times between the different steps and instant packaging can significantly improve efficiency. This is why SIMALFA® developed adhesives that dry extremely fast and enable an uninterrupted production.

Challenges in the 21st century: The perfect inline production

For the ultimate speed of the inline production and the best quality of the mattress, we designed SIMALFA® 360. This adhesive can be applied one-sided on the foam with a double roller. Before placing the top layer onto the glued foam, the foam with the adhesive goes through a heating tunnel – a process that is referred to as “forced drying” as it lets water evaporate and gives the adhesive its ultimate tack.

Because the adhesive has dried already by the time the second layer is placed on top, handling can continue directly after pressing. The instant tack is so strong that it enables roll packaging immediately after gluing. So, let’s see how this works in a standard mattress inline production:

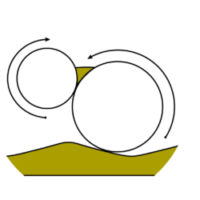

APPLYING

The adhesive is applied to the foam layers using a double roller. Since we invented it for foam application, the concept of the double roller has been adapted by many others all over the world resulting in a standard in the mattress production industry. Our team will be happy to check your equipment and help with advice on set-up and optimization.

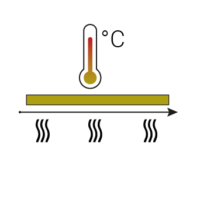

FORCED DRYING

Using infrared drying or a circulating air oven, water is removed from the adhesive, which helps it develop its strong instant tack. This drying process takes no longer than a few seconds, and the production can continue uninterrupted. SIMALFA® 360 is a high solid adhesive whose drying process is completed before assembling the pieces. It is applied one-sided with all types of rollers and in low application amounts.

ASSEMBLY

After drying, the individual parts are put together. If necessary, the workpieces can be easily repositioned, which gives the workers the flexibility to make corrections if required and ensure high quality.

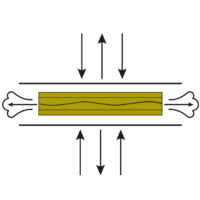

PRESSING

The pressing process guarantees that both parts are wetted with adhesive to achieve the strongest possible tack. After pressing, the workpiece can be processed immediately.

ROLL-PACKING

Workpieces bonded with SIMALFA® 360 can be rolled, packed and handled directly after pressing because the glue has already dried. This reduces the risk of mould or bad odours significantly.

Adhesive application

Forced drying

Assembling

Pressing

Packing

The benefits of natural drying

In case the use of a heating tunnel is not possible or desired, our SIMALFA® 3031 also works without such devices.

Although this adhesive dries naturally, its drying properties are outstanding: Thanks to a unique and proprietary formula, it dries incredibly fast and offers a strong instant tack. With SIMALFA® 3031 the foam pieces are repositionable in the first few moments after contact.

SIMALFA® 3031 stands out thanks to its small application amount and is therefore a cost-efficient solution. With perfectly adjusted roller applicators, no material is wasted. Because many manufacturers are used to far less efficient water-based glues from other brands, many tend to apply too much adhesive to the foam. Outdated or unprecise rollers can have the same effect. Our technical experts are happy to advise you concerning these issues.

Efficiency and sustainability: are they compatible?

In the production industry, efficiency, low costs, and high quality are what keeps you in business. Sustainability is often seen as a nice-to-have, but it seems rather incompatible with the other requirements due to several aspects negatively influencing the eco-friendliness of a product.

As we have seen above, SIMALFA® fulfils multiple criteria in terms of

- cost-efficiency

- speed

- easy handling

- quality

Additionally, SIMALFA® is the right choice to protect the environment as well as the health of your workers. Many adhesives contain solvents, which are toxic and therefore harmful for people and the planet. SIMALFA® refuses to use any solvents in their products. Several chlorine- and halogen-free formulated adhesives such as SIMALFA® 360 – the inline specialist we presented above, are offered by SIMALFA®. Sustainability is all about saving important resources and has been a great ambition for SIMALFA® since the company’s foundation.

Our adhesives consist of up to 70% water and therefore contribute strongly to a circular economy. We are pioneers in the field of water-based adhesives for the foam-bonding industry and we will continue striving for even more sustainable and eco-friendly products to support the recycling process of mattresses – you can read all about that here. But our commitment goes beyond the composition of our products: With the solar panels on the roof of our headquarters in Switzerland, we even produce our own sustainable energy.

Secure your personal appointment

Do you need support or advice? We love to share our know-how. Schedule your appointment now!

Read more articles

SIMALFA®: Solutions for mattress manufacturing

Pack mattresses immediately after production. Maximize efficiency, reduce storage space requirements and increase process reliability at the same time.

THE NEXT LEVEL for mattress manufacturing

SIMALFA® adhesives can be applied manually or automatically - both with spray guns or roller coaters. Find the right application method for your production.

SIMALFA® Competence Center

SIMALFA® adhesives can be applied manually or automatically - both with spray guns or roller coaters. Find the right application method for your production.