Inline Production with SIMALFA®

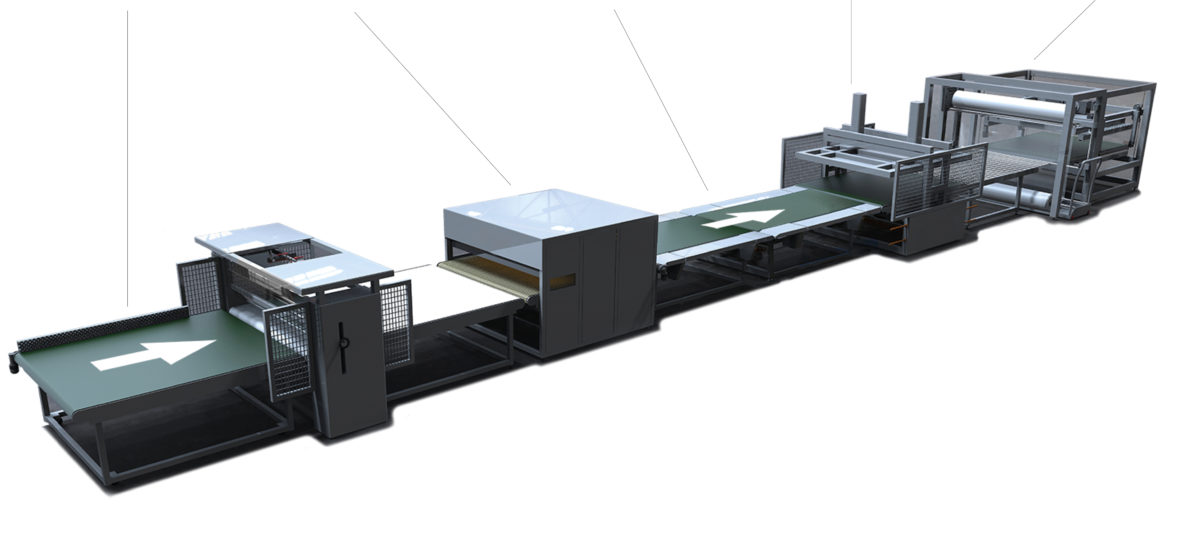

Pack mattresses immediately after production with the especially for the inline production designed SIMALFA® adhesives. Maximize efficiency, reduce storage space requirements (no temporary storage) and increase process reliability at the same time. Ideal for the efficient, time-saving and cost-effective bonding of foams.

Inline production with SIMALFA®

Conventionally bonded foam mattresses require several hours of drying time until the liquid content of the adhesive has vaporized so far, that a problem-free packaging is possible. Thanks to the specially designed adhesives for inline production, the drying process can be significantly shortened. The SIMALFA® 360 adhesive enables immediate packaging without a “memory effect” in roll packed mattresses. This maximizes your production and minimizes your storage costs.

Speed and state-of-the-art formulation technology

In addition to the time you save in the production of your mattresses, you also rely on state-of-the-art formulation technology. SIMALFA® 360 is a one-component adhesive formulated on the basis of the SIMALFA® CR-free technology.

SIMALFA® inline production enables just-in-time manufacturing

You operate an online sales channel and orders are to be assembled, packed and shipped on the same day?

With SIMALFA® inline production, you produce mattresses without waiting times or temporary storage and thus save valuable time in your manufacturing process.

Assemble, pack, ship – it’s that easy!

Production

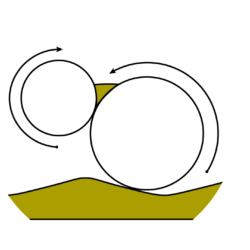

SIMALFA® 360 is applied by roller to the foam parts you want to bond. One-sided adhesive application is sufficient, thanks to the special formulation of the adhesive.

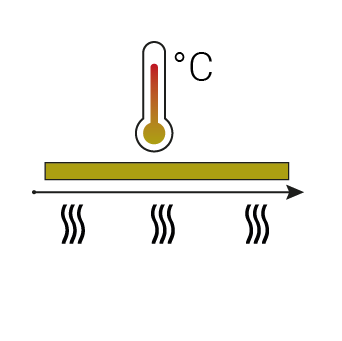

Extract water from the adhesive with an infrared drying tunnel or a circulating air oven and activate the strong initial tack of SIMALFA® 360.

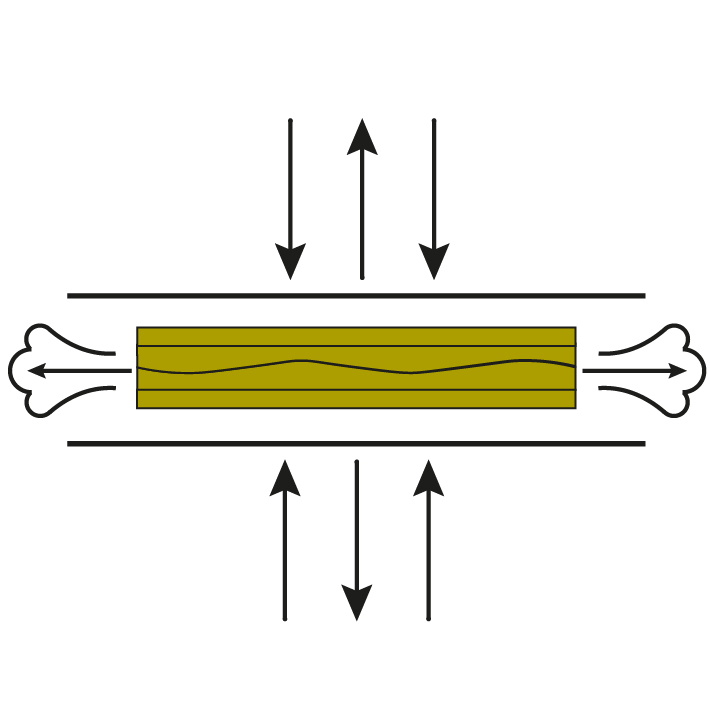

After drying, the individual parts are joined together. If necessary, the foam parts can also be easily repositioned in this step. This gives you the flexibility to easily and quickly do corrections.

The pressing process activates SIMALFA® 360 and the adhesive obtains its final adhesion. After pressing, the workpiece can be further processed immediately.

Bonded foams can be rolled, packed and transported immediately after being pressed. Long drying times, high space requirements and the so-called “memory effect” are a thing of the past. This makes SIMALFA® 360 the first choice for an efficient mattress production.

Advantages of the system:

- Inline production

- Immediate packaging

- Maximum efficiency

- High process reliability

- Time savings in production

- Immediate packaging

- No temporary storage

- No memory effect

The efficient adhesive

SIMALFA® 360 is a high-solid, solvent-free dispersion adhesive for the bonding of foams by roller application. Fast drying, high flexibility and one-sided application distinguish SIMALFA® 360 as the adhesive for efficient producers. Pack and ship your workpieces immediately after pressing. And because there is no memory effect on the end product, SIMALFA® 360 is ideal for roll packing.

Efficient

Designed for maximum efficiency

Solvent-free

100% VOC- and halogen-free

Solids

74% solid content

Application

Only 1-sided application needed

Storage time

No temporary storage

Benefits with SIMALFA® 360:

- For inline production

- High instant tack

- Reduced adhesive consumption

- Immediate packaging

- Suitable for roll packing

- No memory effect

- One-sided adhesive application

- Solvent-free