UV technology for foam-bonding

We are the first adhesive manufacturer to make adhesives visible at the press of a button.

Fast, precise working requires that you are able to recognise what’s happening at a glance. UV technology enables you to visualize adhesives at the press of a button and make it disappear again at the press of a button. As a result, you can make your work processes faster and more precise, but also minimise adhesive use.

The UV adhesives were formulated to ensure they begin to glow when they are exposed to UV light. This means that you can recognise exactly which workpieces have already been sprayed with adhesive and which have not. If you switch off the UV light, the adhesive can no longer be seen on the end product. Have a look at the product list below for more details.

Properties

- More precise working

- Better quality of end products

- Clean working surfaces

- Less waste of adhesive

- Bonds to a multitude of surfaces

- Very short drying times

- High yield

- Faster working

- Repositionable

- High temperature resistance

- Soft glue lines

- Solvent-free

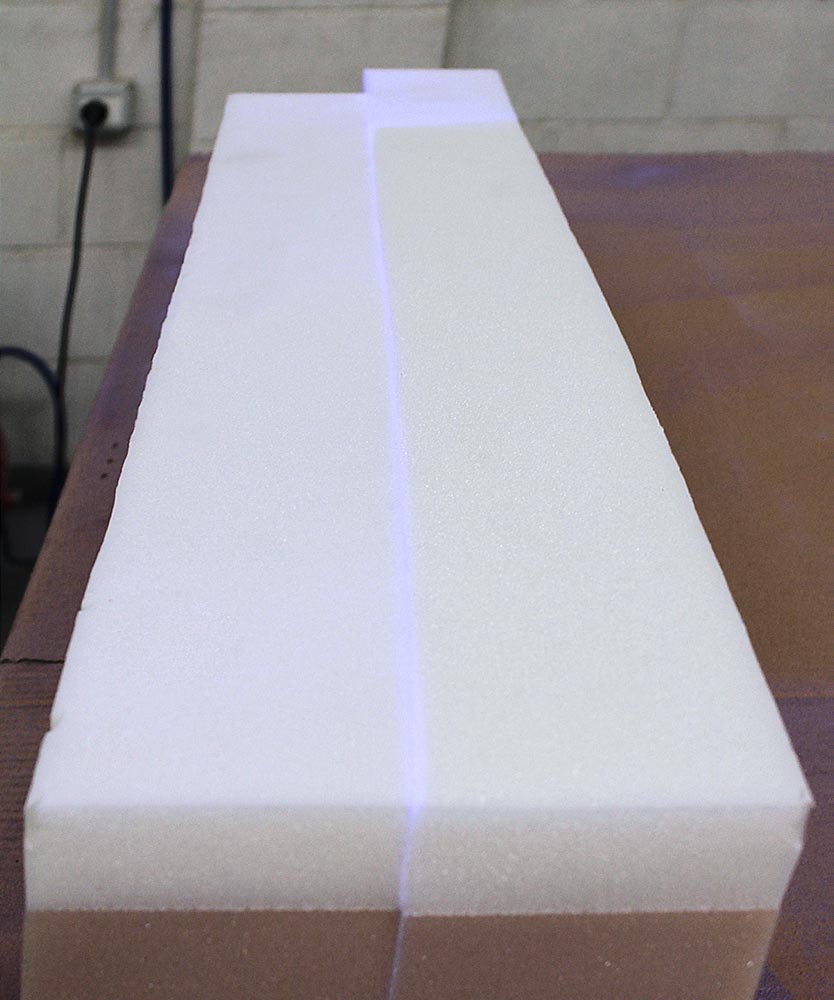

Without UV technology

With UV technology

Areas of use

Foam converting, mattresses and upholstery industry, transportation, packaging, etc.

Most bonded materials

Used for all kinds of upholstery applications and materials, such as foams, cloth, polyester wool, cotton, wood, plastic, cardboard, rubber, leather, artificial leather or non-woven.

Application types

- Spray guns

- Automatic spray application

- Manually with brush