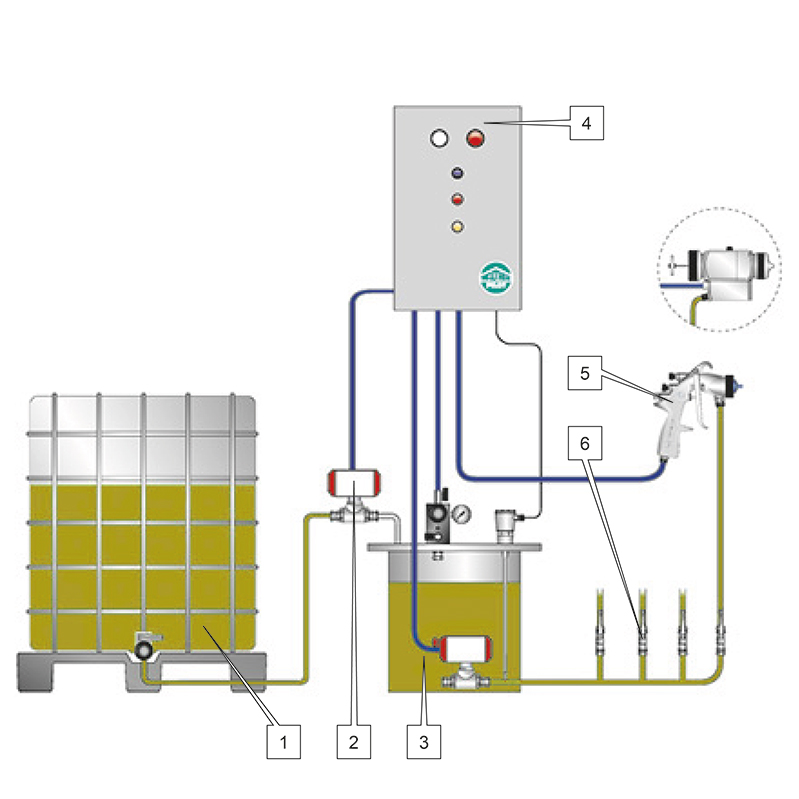

Vakubond System

If you want to have central material supply and a material-saving adhesive delivery: here is the solution. The Vakubond system works entirely without pumps. The newly developed automatic filling system regulates the flow of adhesive from the container into the pressure tank clean and material-friendly. From there, the pulsation-free adhesive distribution to the spraying stations takes place. The container does not need to be raised.

Up to max. 10 work places can be supplied with material. Conveyor lines up to 25 m are possible. The system works gently, as there is an unhindered flow of material.

Advantages of Vakubond System:

- Suitable for several spray guns or workplaces

- Delivers adhesive over long horizontal distances

- Suitable for low room heights

- Suitable for places that cannot be reached with a forklift

- No long filling times

Restrictions:

- High investment costs compared to the SIMALFA® Free Flowing System

- Maintenance costs

- Cleaning effort