Adhesive applications in foam glue

The quality of an adhesive does not just lie in a strong and long-lasting bond. There are further criteria to define its value and suitability for a manufacturing process, such as the application equipment.

SIMALFA® offers a complete solution that has been specifically adapted to today’s manufacturing requirements. The system unit includes high quality equipment that has been perfectly adjusted to the adhesive. The correct setup of the workspace is key for an easy and efficient production process. SIMALFA® assists their customers in installing the equipment and the workspace and optimizing the process afterwards. It is our goal to enable successful bonding processes as a whole. In this article, we show you different adhesive application systems.

Types of application: Roll or spray?

Of the two different possibilities – rolling and spraying – to apply adhesive to the workpieces, roller application is most commonly seen in mattress manufacturing because of the fast and even application on the big, flat surface of the mattress foam.

For optimal results, SIMALFA® invented the double roller application process for mattresses, with which the adhesive can be applied much more deliberately. By adjusting the width of the gap between them, the amount dispensed can be regulated. This method was initiated by SIMALFA® nearly 20 years ago and is widely used today. There are several benefits to these roller coaters, such as the small application quantity used and their high precision. The adhesive is applied evenly and no material is wasted. After installation, the whole process runs very efficiently.

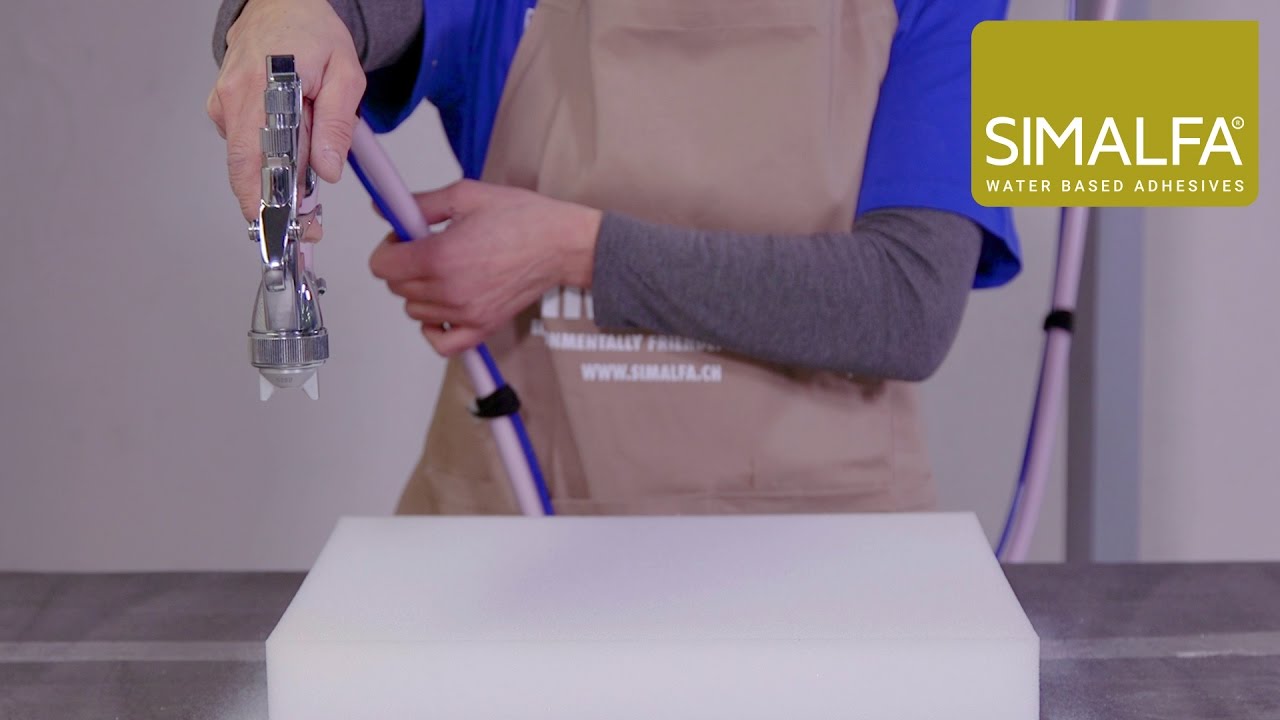

Contrary to that, manual spray application is more often used in the upholstering and foam converting industries. Spray application is advantageous for smaller and variable foam pieces because of its flexibility. The handling of the spray gun can be learned with ease. We offer different spray guns depending on the individual requirements of our clients. If overspray is an issue in your production, you can use our specifically developed line of adhesives that are applied in a net-like spray pattern, eliminating any overspray without residues. The OF-line can be applied just as easily with our spray guns.

We also offer adhesives that can be applied as one or two components, and have developed a patented system with a spray gun that allows adding an accelerator on-demand. At the push of a button, the instant tack of your adhesive gets a boost. This is useful, for example, in the production of chairs, where the foam is bent around the edges of wooden parts. In such applications, there is a lot of stress on the glue, but with a stronger instant tack, the pieces can be held together easily. All our spray guns are perfectly adapted to SIMALFA® adhesives and are ergonomic. Additionally, we have developed a series of products suitable for one-sided application.

Lastly, our adhesives can be applied with an automatic spray system, which can be beneficial in certain contexts, such as repetitive applications or high-volume production.

Conveying the adhesive

Before the adhesive can be rolled or sprayed onto the material, it needs to be conveyed from its storage container to the workplace. We offer several systems to simplify this procedure. Our adhesive can be purchased in boxes of 20kg up to 1000kg containers. Because our clients’ requirements vary greatly, we have developed several delivery systems. We are happy to support you in installing the systems and starting the process.

FREE FLOWING SYSTEM

The easiest way to transport the adhesive to the workplace is by using our Free Flowing System that makes use of gravity: Just by placing the container above the workplace, the adhesive can flow down towards the gun or roller. No pressure pot is needed, and this easy system also works for two-component adhesives or the on-demand system. For spray application in different workplaces, we have developed the movable free-flowing rack. It can hold our 20kg adhesive boxes and is already equipped with the SIMALFA® spray gun and the matching hose kit.

Easy-2-Pump System

The storage container does not necessarily need to be placed above or at the same level as the workplace, it can simply be placed on the ground. If the adhesive needs to be conveyed over greater distances, several possibilities are available: One option is the Easy-2-Pump System. This system is recommended when using two-component adhesives because it can generate the perfect ratio between the adhesive and the accelerator. Like the Free Flowing System, it enables the supply of several workspaces thanks to a pump system.

Pressure pot

Alternatively, a pressure pot can be installed. The adhesive is gently transported thanks to a controlled air pressure. Even though the pressure pot works without pumps, several workspaces can be supplied with this system. It fills up automatically. For specific situations, a mobile pressure pot can be deployed. Thanks to built-in rolls, the container can be transported over further distances and is therefore very flexible.

Another specialized system is the VAKUBOND: As soon as the adhesive is applied, the required amount is sucked out of the storage container into the pneumatically controlled container and conveyed to the workspace from there.

Additional services

SIMALFA® will assist you in finding your perfect solution and support you in installing all the equipment required – from the installation of the container to the transportation system and the application method. A commonly encountered challenge is to only apply the small amount of adhesive that is actually required, and we can help you reduce the quantity and therefore keep down your costs.

Additionally, we also offer other pieces of equipment, such as spray walls with an integrated fan to keep the air clean. And of course, we will help you if you need any spare parts and support you with the maintenance of your equipment. In general, maintaining our equipment is quite simple, especially the Free Flowing System. But of course, the material will last longer if it is regularly cleaned and maintained. Our experts are happy to show you the optimal maintenance procedure after the installation of your new adhesive application system.

Secure your personal appointment

Do you need support or advice? We love to share our know-how. Schedule your appointment now!

Read more articles

Adhesive types

The proper type of adhesive needs to be chosen based on the requirements of the production process. We will show you how you can find the perfect adhesive for your individual needs.

How rolled mattresses optimize your production

Long drying times, high space requirements and the so-called "memory effect" are a thing of a past. SIMALFA® 360 is the first choice for an efficient mattress production.

Improved efficiency with fast drying adhesives

In the production of mattresses, short waiting times and instant packaging can significantly improve efficiency. For the ultimate speed of the inline production and the best quality of the mattress, we designed SIMALFA® 360.